- National Science Academy

- «The Physical-Technical Institute of the National Academy of Sciences of Belarus»– PTI NAS of Belarus

Potential Technology Innovation

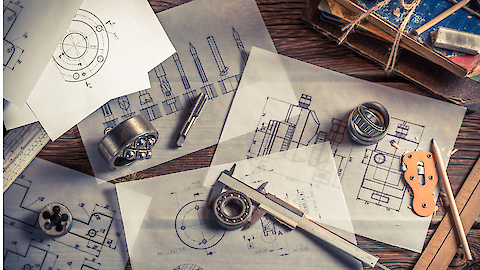

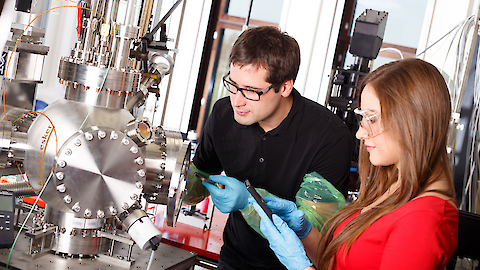

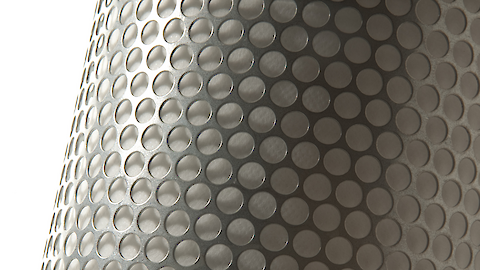

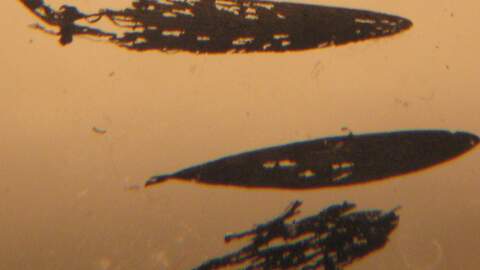

The institute activities are also connected with manufacture of new multifunctional materials and coatings with improved characteristics for machine building, microelectronics, medicine and other fields, diamond abrasive composites for tools, tool production technology, testing and certification of tools. We deal with the development of high-speed methods of heat treatment of metals and alloys, including protection elements of armour vests, recycling of pure non-ferrous and precious metals waste, recuperation of diamonds. Diagnostics and development of plans for repair-and-renewal operations for main pipelines, gas pipelines and vessels under pressure, certification of tools, metallographic and X-ray diffraction research.