- Ministry of Education

- Belarusian National Technical University

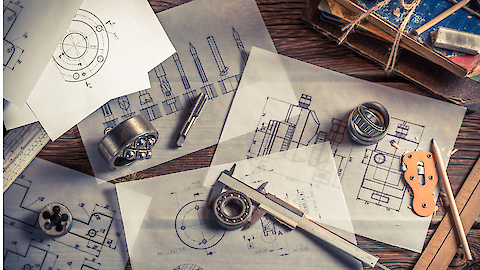

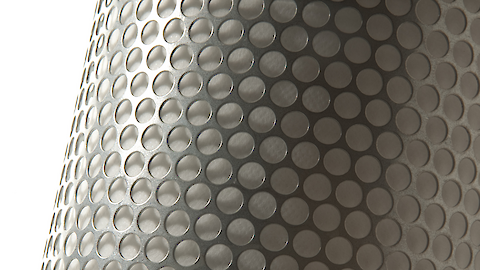

- Technology and equipment for applying protective coatings

Technology and equipment for applying protective coatings

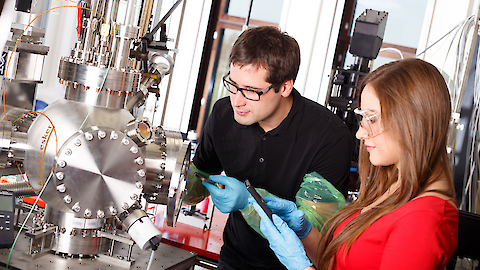

Laser welding technology has a number of characteristic, attractive, high-quality joints. These features include:

- Ultrahigh value of energy in a zone of influence of a laser beam. This allows you to reduce (2 ... 5 times) the width of the seam, to reduce the deformation of parts (up to 10 times);

- Rigid thermal cycle with high speed characteristics and cooling makes it possible for laser welding. This allows you to reduce the effect of phase and structural transformations in the heat-affected zone, lead to softening, cracking, lower corrosion resistance, etc.

- the sharp focusing of the beam and the possibility of transmitting it over considerable distances allow welding in hard-to-reach places, for example, in recesses of corrugated structures, internal cavities, etc.

- environmental friendliness: when welding does not form slags, a small amount of welding vapors and aerosols.

Views count

6 234

Республика Беларусь, 220013, г. Минск, пр-т Независимости, 65

Contact

Республика Беларусь, 220013, г. Минск, пр-т Независимости, 65